Spray Foam Specifics

Spray foam is made from two materials, isocyanate and polyol, that react when combined. It is sprayed as a liquid foam that expands and hardens to insulate and air seal. It easily fills open areas and sticks to small gaps and cracks. It sticks to everything it is applied to, making it ideal for attics, crawl spaces, and small or hard-to-reach places.

R-value measures how well an insulation resists heat flow. The higher the number, the better the thermal resistance and insulating power. While R-value is important, it’s not the only thing to consider for our hot, humid climate. Air sealing and moisture control are just as critical. Closed-cell spray foam is often the smartest choice for your Florida home thanks to its high R-value and ability to block air leaks and humidity.

Most of our state falls in climate zone 2A, which is classified as a hot, humid climate. The 2023 Florida Building Code is based on the 2021 International Energy Conservation Code (IECC). Effective July 1, 2025, the new section 553.9065 Florida statutes provides an alternate compliance method for unvented attics using R-20 air impermeable insulation such as closed-cell or open-cell spray foam applied to the underside of the roof deck. View the Digital Codes online to check out the specific R-value requirements for new homes in Florida.

Spray Foam Comparison

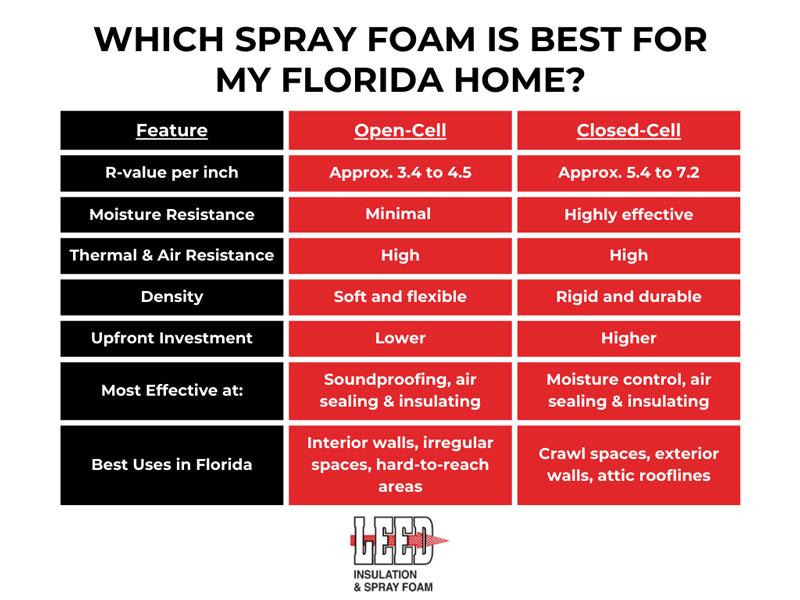

You should consider open-cell foam for interior applications like walls where breathability is important. It’s great for noise reduction but doesn’t block moisture. Closed-cell foam is best for areas exposed to humidity, potential flooding, or where extra structural strength is needed, like attic rooflines, crawl spaces, and exterior walls.

Check out this chart for a quick side-by-side comparison:

Spray Foam’s Properties

Pest Control

Spray foam helps deter pests by sealing gaps and cracks that insects and rodents use to enter your home. Since it’s made of synthetic materials, it’s also not a food source for pests. In Florida, where pests are common, this can make a noticeable difference. Spray foam works best alongside proper pest-control methods. Think of spray foam as a strong deterrent and barrier, not a complete solution.

Soundproofing

Yes! Open-cell spray foam is excellent at reducing noise from neighbors, traffic, or even loud AC units. Its soft, sponge-like structure absorbs sound waves and limits vibrations passing through your walls, floors, and ceilings. It’s a great way to help quiet everyday noise, especially in busy neighborhoods or near highways.

Fire Safety

Spray foam is fire-resistant but not fireproof. It has a Class 1 fire rating that meets building code standards when installed properly. This means it will resist flame spread and smoke development within safe limits. Certain applications require a thermal or ignition barrier (like drywall or a fire-rated coating) over the foam for added protection.

Our team depends on Enverge SucraSeal spray foam for added fire safety. It’s formula retards flames and smoke, eliminating the need for an ignition barrier.

Hurricane Preparedness

Closed-cell spray foam hardens into a dense, rigid material that bonds tightly to roof decking, walls, and studs. This property helps distribute stress more evenly and reduce flex during high winds. This is very valuable in our hurricane-prone climate.

The Department of Energy says: “Studies at the University of Florida and elsewhere have documented the structural advantage of using closed-cell spray foam to glue roof decking to trusses in hurricane-prone areas. Similarly, studies have found that the racking strength of frame walls is substantially increased when closed-cell spray foam is used in the frame cavities: an advantage for seismic and hurricane zone construction.

Spray Foam Health & Safety

Off-gassing happens as spray foam cures, releasing small amounts of VOCs (volatile organic compounds). This is temporary, usually lasting 24 hours, while the foam hardens into a solid, safe material. Once cured, spray foam is inactive and no longer emits VOCs. This allows it to provide lasting benefits like energy efficiency, moisture control, and comfort.

It’s important to wait 24 hours after spray foam installation before re-entering your home. This allows the foam to fully cure and off-gas any chemicals. For large projects or poor ventilation, some contractors recommend up to 48 hours to ensure safe indoor air quality.

At Leed Insulation, our professional spray foam installation starts with prep work. We seal the area, protect surfaces, and ensure proper ventilation and safety measures. Next, we mix and spray the foam, allowing it to expand and fill gaps. After the foam has finished curing (about 24 hours), we trim any excess foam, and the area is cleaned.

Spray Foam Savings

Every insulation project is different. The cost of your spray foam project can vary based on:

- The size of the area being insulated

- The type of spray foam used: closed-cell or open-cell

- The thickness required

- Accessibility of the space

- Building code requirements

- Labor

Spray foam offers strong ROI in our state by lowering your energy bills, reducing HVAC strain, and preventing moisture-related damage. Over time, these savings often outweigh upfront cost. Added benefits, like comfort, durability, and structural strength, make it a smart long-term investment in our hot, humid climate.

With proper installation, spray foam insulation can last 50+ years in our coastal environment. Closed-cell foam in particular is a highly effective choice for our harsh climate thanks to its powerful moisture resistance, air sealing abilities, and durability.